Stan

I bought a shim and push rod kit from RPI.

I had the original heads skimmed and used composite gaskets. I checked the pre-load which was quite a bit out. When I fitted the shims it brought the pre-load to the correct figures quoted. people often say "for all it cost" and they are right, why spend a fortune on a new cam and rocker and leave the pre-load out of spec for £20. Also very easy job to do just remember to fill the followers with oil first.

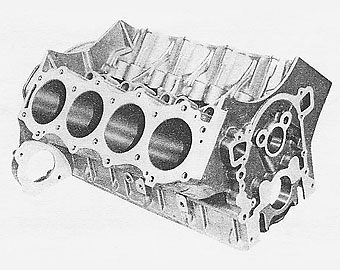

I refitted the outer bolts but left not fully torqued up. Did you ever read the history of the V8? one of the yank models had an extra row of bolts on the push rod side of the cylinder head which gave 6 bolts around each cylinder, with this bolt deleted from the casting it left the 5 bolts, It makes sense that 4 evenly space bolts per cylinder is better . Though you've got to wonder how much of a problem it really was though, for all the V8 models built how many actually blew a head?

last week I started the engine for the first time since I did the top end rebuild, sounds awesome but I only ran it for a few seconds whilst setting up the distributor.

Here is a question maybe Harvey can help with. A guy I work with has rebuilt many V8s mostly for boats. When I told him that I had did some top end work he thought I had to run the engine at 2,500rpm for "x" period. Is this the case or was it just to get to oil pumping round?

Colin