truckdoctor

Member

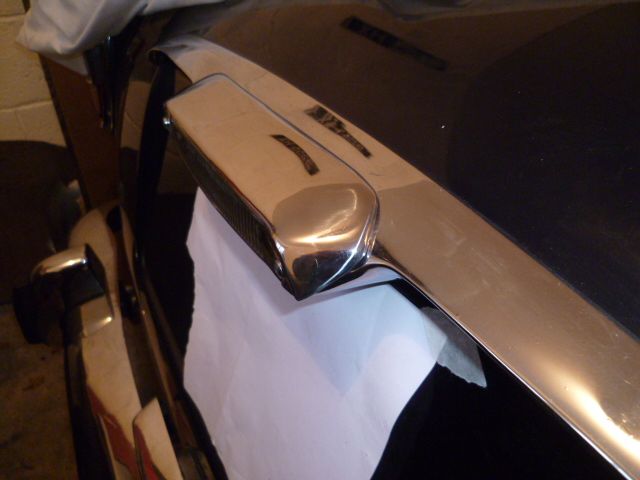

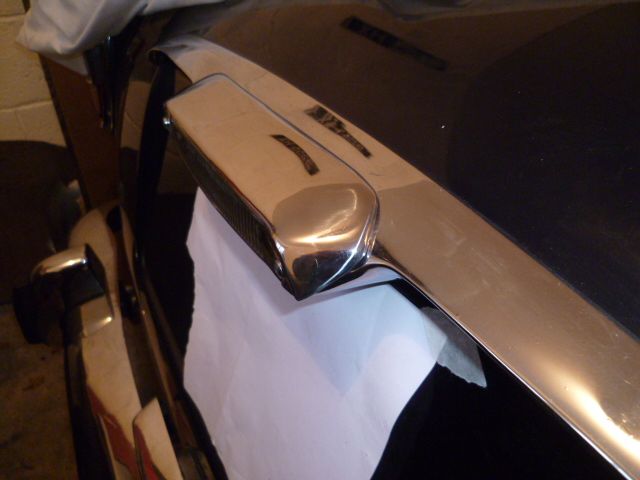

The lamp cover on the boot lid is made of "Mazak"? and when re chromed carries on corroding so I thought of replacing it with stainless, here is my attempt.

Making a cardboard template it's apparent that to make a new piece will involve shrinking the sheet to create the compound curves required. to do this I clamped the roughly bent stainless to the original lamp cover and hit it glancing sideways blows from the smallest hammer in the toolbox, forcing the metal into itself until it began to shrink taking on the shape required.

First a trial attempt

Now I know it can be done here is the method I used to make a complete cover using a piece of stainless roughly cut to shape large enough to make a whole replacement cover.

Forming the bends and clamping over the original

All that hammering has made the steel hard and needs to soften up so gently heating will help

Some more hammering

Here's the old and the new, as you can see it's a little rough and needs smoothing

So I knocked this up, a mini English wheel, made from few bits and pieces lying around

Pushing the piece through the rollers smothed things a little, now for the polishing, starting with a smooth file then wet n dry 360 wrapped around a piece of timber, then 500 and then the polishing mop.

Now time for the fixing flanges, small plug welds and silver solder around the edges

A couple of holes and a final polish

Hope this is helpful.

Steve

Making a cardboard template it's apparent that to make a new piece will involve shrinking the sheet to create the compound curves required. to do this I clamped the roughly bent stainless to the original lamp cover and hit it glancing sideways blows from the smallest hammer in the toolbox, forcing the metal into itself until it began to shrink taking on the shape required.

First a trial attempt

Now I know it can be done here is the method I used to make a complete cover using a piece of stainless roughly cut to shape large enough to make a whole replacement cover.

Forming the bends and clamping over the original

All that hammering has made the steel hard and needs to soften up so gently heating will help

Some more hammering

Here's the old and the new, as you can see it's a little rough and needs smoothing

So I knocked this up, a mini English wheel, made from few bits and pieces lying around

Pushing the piece through the rollers smothed things a little, now for the polishing, starting with a smooth file then wet n dry 360 wrapped around a piece of timber, then 500 and then the polishing mop.

Now time for the fixing flanges, small plug welds and silver solder around the edges

A couple of holes and a final polish

Hope this is helpful.

Steve