Lovel

Member

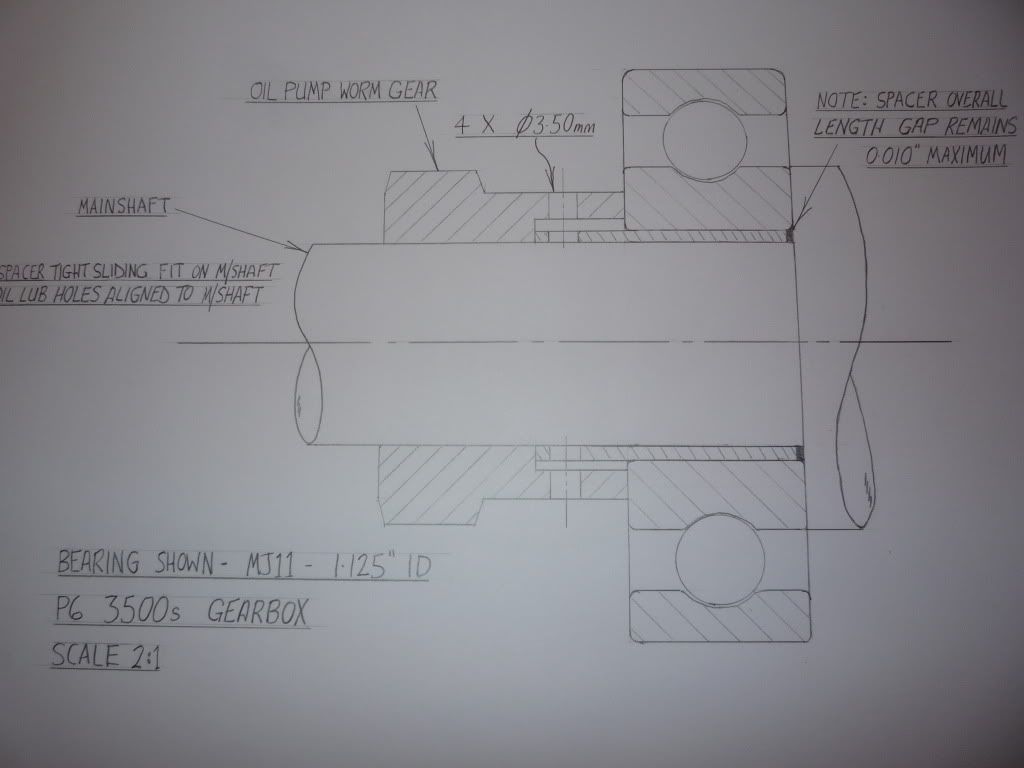

Currently working on the overhaul of my 3500S manual box. The rear mainshaft bearing does not seem too bad on close inspection, however there may be an ever so slight roughness to it when turned, hence I am looking to replace.

The component in question has Rover part number 576208, and the bearing is inscribed with N9181C RHP MJ11/8.

I estimate the dimensions to be 2.813" OD x 1.000" ID x 0.813" Wide

The nearest brg I can find is the same dimensions as above apart from the ID of 1.125"

http://www.bearingstation.co.uk/Product ... J1-1-8-RHP

Has anyone machined a spacer collar bushing to make up the difference, and if so was it long lasting and what material was it made from? or should I just bite the bullet and purchase the original bearing which seems to be available from JRW at an eye watering price.

Gary.

The component in question has Rover part number 576208, and the bearing is inscribed with N9181C RHP MJ11/8.

I estimate the dimensions to be 2.813" OD x 1.000" ID x 0.813" Wide

The nearest brg I can find is the same dimensions as above apart from the ID of 1.125"

http://www.bearingstation.co.uk/Product ... J1-1-8-RHP

Has anyone machined a spacer collar bushing to make up the difference, and if so was it long lasting and what material was it made from? or should I just bite the bullet and purchase the original bearing which seems to be available from JRW at an eye watering price.

Gary.