corazon

Well-Known Member

Depends how high lift your jack is and how high you want to lift the car.

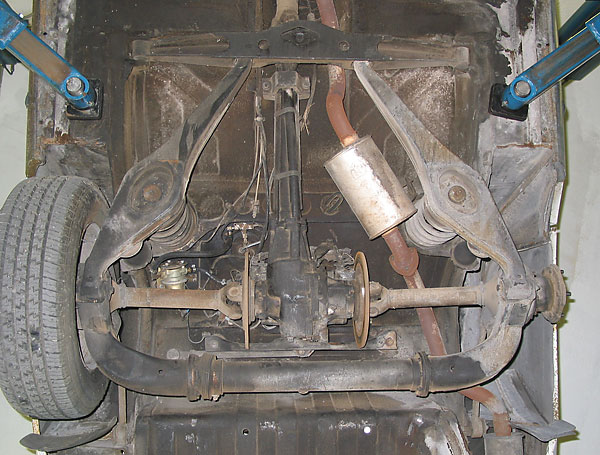

I prefer to not use a block of wood on the rear jacking point as that metal block usually sits quite nicely in the jack saddle and when you raise the car you want the jack to be able to roll a certain amount. When you use a block of wood, there's the potential for that to rotate or slip out after a certain height/angle. I'm very cautious with things like this, but have had countless p6s up on a very high lift jack from this point 3 or 4 feet in the air with no problems.

If however you just want to get the wheels high enough to remove them, a block of wood at the rear should be fine if it's large enough.

I sometimes favour jacking on the rear crossmember, but you need a long reach jack to get enough front to rear angle without pulling the car over to one side too much if that makes sense. It's quite a bit lower though so doesn't need a particularly high lift jack to get the wheels off the floor.

Jim

I prefer to not use a block of wood on the rear jacking point as that metal block usually sits quite nicely in the jack saddle and when you raise the car you want the jack to be able to roll a certain amount. When you use a block of wood, there's the potential for that to rotate or slip out after a certain height/angle. I'm very cautious with things like this, but have had countless p6s up on a very high lift jack from this point 3 or 4 feet in the air with no problems.

If however you just want to get the wheels high enough to remove them, a block of wood at the rear should be fine if it's large enough.

I sometimes favour jacking on the rear crossmember, but you need a long reach jack to get enough front to rear angle without pulling the car over to one side too much if that makes sense. It's quite a bit lower though so doesn't need a particularly high lift jack to get the wheels off the floor.

Jim