Pilkie

Active Member

Hi Ron.

I havent decided which approach I will use yet,but if there is any slight hint of pitting on the head surface,that doesnt warrant a skim,I will probably use a sealant as well!

Fortunately I do have a pair of spare heads,and a complete good engine.

Will look at headsets at a show I am going to next weekend,although I do have a couple in stock,,I think?

Hi Scott.

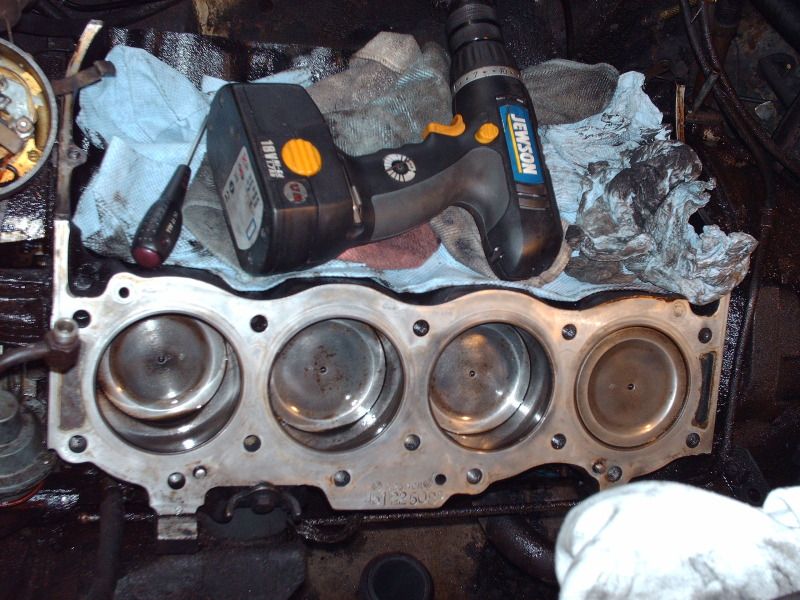

There has been an ongoing problem with a minor build up of pressure for a while,and ive not been able to pinpoint which of the 8 cyls its being caused by!

Its not caused any problems till now!

I know its not the thermostat as I changed that not long ago,and was getting the same symptoms after doing so.

Water pump was also replaced earlier this year due to a leak!

I am pretty sure its either a faulty gasket or if unlucky a crack in a head!

What I should of done is looked into each plug hole when I knew there was water in there,that would tell me the offending headgasket.

Its not much more work to replace both while its stripped down anyway!!

Its a good excuse for a good clean up,decoke,repaint the heads and rocker covers, inlet manifold etc and sort out the front crankseal that I think is leaking!

Just need to make sure I can get the TR6 in and out of the garage if I need to go anywhere!

I havent decided which approach I will use yet,but if there is any slight hint of pitting on the head surface,that doesnt warrant a skim,I will probably use a sealant as well!

Fortunately I do have a pair of spare heads,and a complete good engine.

Will look at headsets at a show I am going to next weekend,although I do have a couple in stock,,I think?

Hi Scott.

There has been an ongoing problem with a minor build up of pressure for a while,and ive not been able to pinpoint which of the 8 cyls its being caused by!

Its not caused any problems till now!

I know its not the thermostat as I changed that not long ago,and was getting the same symptoms after doing so.

Water pump was also replaced earlier this year due to a leak!

I am pretty sure its either a faulty gasket or if unlucky a crack in a head!

What I should of done is looked into each plug hole when I knew there was water in there,that would tell me the offending headgasket.

Its not much more work to replace both while its stripped down anyway!!

Its a good excuse for a good clean up,decoke,repaint the heads and rocker covers, inlet manifold etc and sort out the front crankseal that I think is leaking!

Just need to make sure I can get the TR6 in and out of the garage if I need to go anywhere!