vaultsman

Well-Known Member

Ever since I got her, I've hankered after the 5-speed box I've felt she was crying out for, so when I won what, on the face of it, seemed a decent box, bellhousing and remote complete...I'm afraid it was time for Rebekah to take (yet another) back seat.

As always, time to spare is the killer but, having discussed the job through a few PM's with Harvey and some notes from Dave McSweeney (many thanks both!) I plumped for getting on with it myself.

(Aside to Phil Robson - see how I'm leaving the field clear for you? )

)

This is the baby...and a heavy old lump it is! :roll:

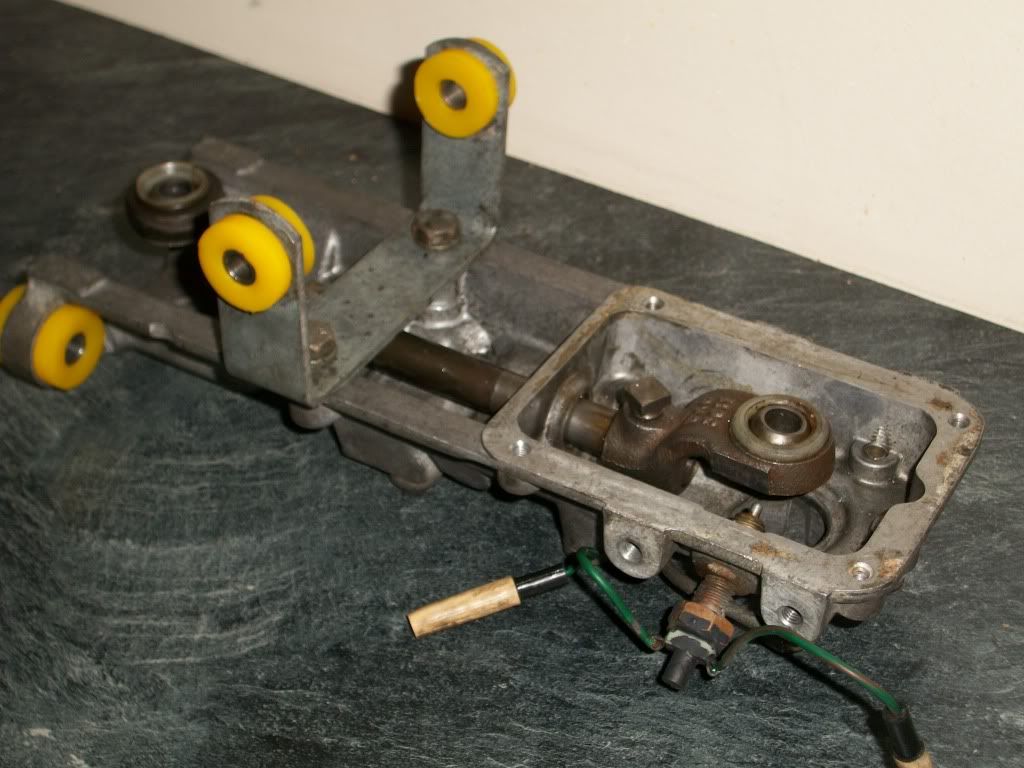

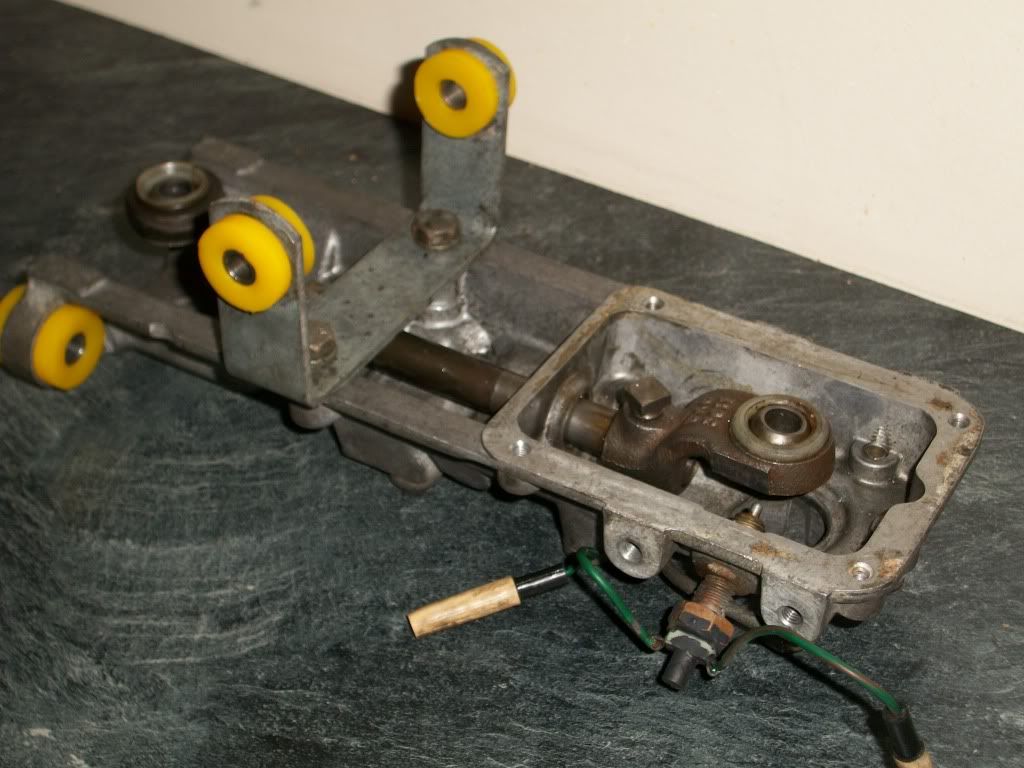

First job, have a good look over the remote. The mounting bushes were shot, and I'm not sure what that rubber blob was that passed for one of them!

There was a tad too much play in the selector shaft for my liking, so I turned up a couple of phosphor bronze replacements...

Reassembled with new polybush mounts...no play at all in the shaft now and, with a helping of grease, it moves like silk.

Having done the interior and engine bay prep work through the week, today was getting her jacked up ready for me to slide under...

Loving these CJ Autos adjustable ramps - can't run to the hydraulic ones but these take no time at all with a socket...and a flexible wrist! :wink:

Downpipes and front exhaust section and the slave cylinder's off, rear flange of the prop dropped down but the front flange seems a bit reluctant to separate. :twisted:

More pics anon...but for now...SWMBO's visiting for the weekend and she's done me chicken, leek and potato bake! Excellent!

As always, time to spare is the killer but, having discussed the job through a few PM's with Harvey and some notes from Dave McSweeney (many thanks both!) I plumped for getting on with it myself.

(Aside to Phil Robson - see how I'm leaving the field clear for you?

This is the baby...and a heavy old lump it is! :roll:

First job, have a good look over the remote. The mounting bushes were shot, and I'm not sure what that rubber blob was that passed for one of them!

There was a tad too much play in the selector shaft for my liking, so I turned up a couple of phosphor bronze replacements...

Reassembled with new polybush mounts...no play at all in the shaft now and, with a helping of grease, it moves like silk.

Having done the interior and engine bay prep work through the week, today was getting her jacked up ready for me to slide under...

Loving these CJ Autos adjustable ramps - can't run to the hydraulic ones but these take no time at all with a socket...and a flexible wrist! :wink:

Downpipes and front exhaust section and the slave cylinder's off, rear flange of the prop dropped down but the front flange seems a bit reluctant to separate. :twisted:

More pics anon...but for now...SWMBO's visiting for the weekend and she's done me chicken, leek and potato bake! Excellent!