Over on Geoff's thread, the discussion turned to extractors and exhaust systems. So to continue with the discussion here I'll post again what I wrote there.

"Hello Chris,

In Australia, the term extractors actually applies to both the 4-1 and the 4-2-1 designs. To further differentiate, tri-y applies to 4-2-1, so tri-y extractors as opposed to extractors.

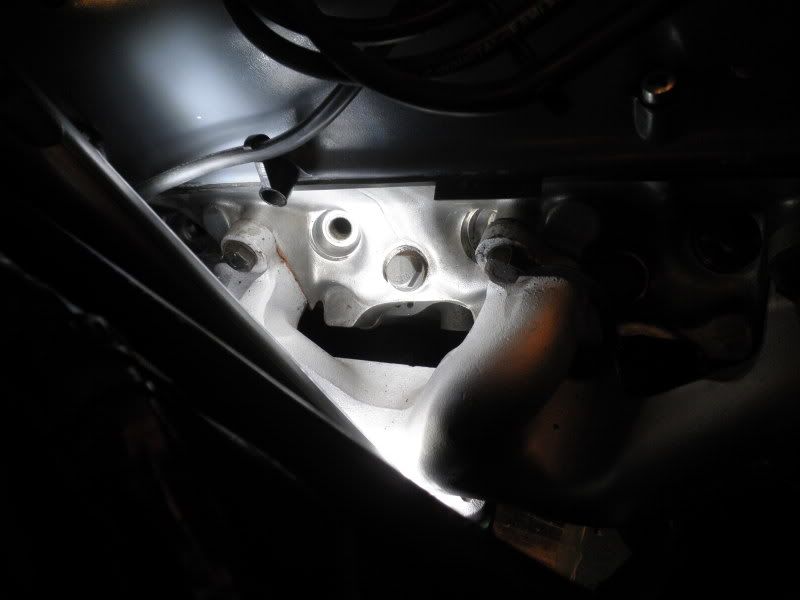

I did a fair amount of investigating prior to choosing to stay with the cast manifolds. I looked at both 3.5 and 3.9 Range Rover manifolds, which by their design are a 4-2-1 system. Both sides are distinct as tri-y systems usually are, but this presented a problem as there is insufficient space to fit from memory the n/s. So I would need to buy two pairs and use what would normally be the o/s on both sides. I would then have 4 X 1.5" down pipes to contend with. Rather than joining all 4 into one large 3" pipe at the transmission, I'd probably have opted for joining directly beneath the manifolds and then running two 1 5/8" pipes into a 2 1/4" or so main pipe. I also looked at 4.6 factory manifolds but their design ruled out fitment all together. I measured the ports, both entry and exit for Range Rover 3.5, 3.9 and 4.6 litre factory manifolds and compared to the P6 manifolds. Surprisingly, the P6 manifolds have the largest entry ports, but the smallest exit ports at 1 1/2". The 3.5 and 3.9 have two 1 1/2" exits per manifold and the 4.6 have a single 2 1/4" exit.

If I opted for a custom 4-2-1 system, I would have chosen 1 1/2" primaries, 1 5/8" secondaries and a 2" collector feeding both sides into a 2 1/4" main pipe.

As it stands I kept the P6 factory manifolds with their 1 1/2" down pipes feeding into a 2" main pipe which increases to 2 1/4" then 2 1/2" and finally 3" before exiting. Sound wise it is bl**dy loud when revved, goodness knows how much louder it would have been with a custom set of pipes too.

Ron"

Now to continue the discussion with new material.....

I can’t say how much of a loss the standard cast iron P6B manifolds may have cost me compared to a set of extractors, but what I can say is that with everything set as it is now, high flow air cleaners, needles polished, timing advanced, large bore exhaust system with flow through muffler and resonator in place, the dyno run would tell all.

At the time my 4.6 had only seen 2500 miles (4000km), so it might be fair to say that if a repeat was undertaken, the likely hood is a further improvement given the engine was still quite tight at the time.

The dyno run showed 142 Horsepower being delivered to the rear wheels @4750rpm. My engine is built as a Range Rover engine with the emphasis on torque, so in that regard was most impressed.

Working backwards to estimate engine power, transmission losses of 17% are pretty normal for an auto transmission, especially one without a lock up torque converter. So that delivers 171 Horsepower to the flywheel. Power loss from all the ancillaries is in the order of 33 Horsepower, so gross engine output is in the order of 204 Horsepower which is as would be expected from such an engine, and in line with similar Thor engines as fitted into Range Rovers.

So on the face of it, the cast iron manifolds don’t do too badly. I expect that my exhaust system after that may have helped quite a bit.

Ron