Dave - really sorry for not replying sooner, I have no information on the 5-speed conversion other than what is here on the forum.

Update time.... Here it is next to my youngest brothers Series 3 - it got its first MOT in 14 years a few weeks ago.

So an update here is well overdue, the car has been, well…. Just running – not really missed a beat at all in the last year until recently.

With this new state of equilibrium my attention had mainly turned to my Land-rover 90, so it was the niggly little things that got sorted on the P6 here and there.

First of these was the non-functional intermittent wipe. Following the guide here on the forum I removed the motor, stripped, cleaned and regreased it, and sorted out the vacuum capsule on the delay unit. I am glad I did this, as it turned out that two of the rubber mounts had parted company and it was only held in place with one!

With everything refitted the wipers now work as they should, including intermittent – I no longer have to switch on,off,on,off,on,off in light drizzle – bliss! The upshot to having cleaned everything, regreased and secured it to the base unit properly is that my sweep is slightly better and the wipers definitely run quicker.

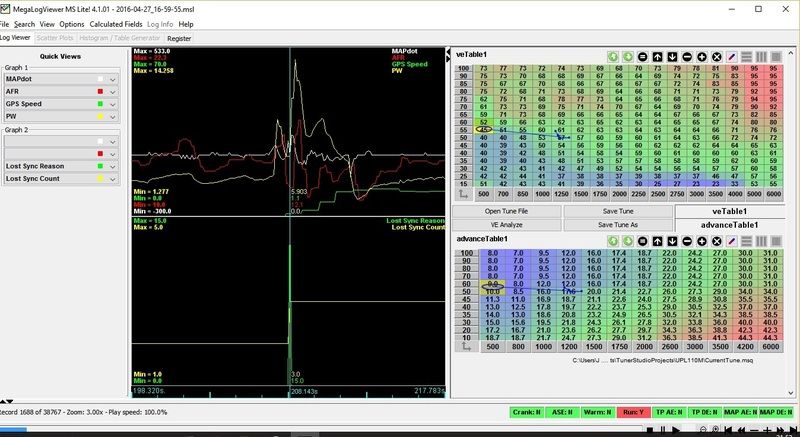

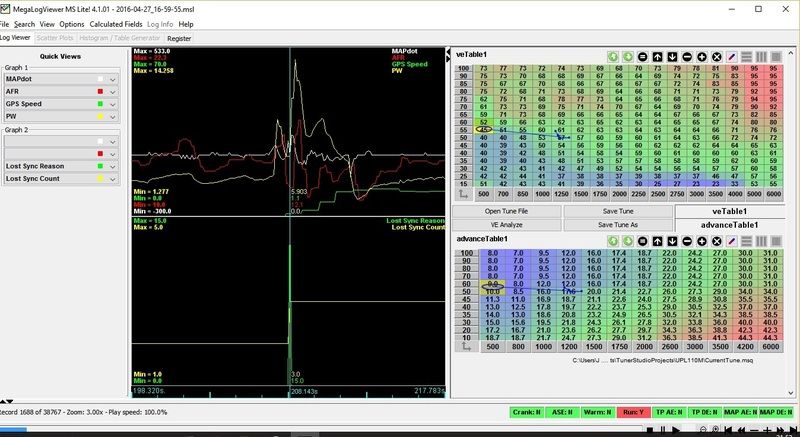

After running around with my acceleration enrichments barely adjusted from stock I decided that I had had enough of the slight hesitation sometimes apparent when hitting the throttle. Data logging my journeys, reviewing and making small incremental adjustments has got things dialled in a lot more closely now, although I still haven’t got it perfect yet. A few big changes that helped were changing the MAP lag factor to reduce response time (MS2 defaults everything to 50 out of 100, with 100 being no lag- MS1 doesnt have these lag factors so there isn't an issue).

This extra fuel going in then meant my fuel consumption dropped slightly, so I had to look at where I could pull it back! An obvious one was the warm-up enrichment. Megasquirt tuning is done through an excellent piece of software called “Tunerstudio” and with this you can tune your VE-table and warm-up automatically.

On reviewing the warmup tuning settings I had previously used I noticed that Tunerstudio was applying an offset to the warmup. Rather than simply tuning to achieve your target AFR, it can make the mixture richer/leaner depending on temperature. I had used the default curve previously which was adding half a point of richness when cold. This was removed so that the software was targeting normal mixtures throughout the warmup cycle, then after leaving the car overnight it was retuned. This entailed starting the car with the laptop connected and letting it idle up to normal temperature, while the software did its thing. Easy!

This pulled things back to previous normal levels of approx. 25mpg and things were good for a while.

Then about a month ago I started to get a small bit of bucking now and then when accelerating, the car would do it once or twice over the course of my 35 mile trip to work. I firstly assumed that this was down to my latest changes to accel enrichment, so took some datalogs – I couldn’t see any reason for it, so continued using the car and continued logging.

Then one afternoon on the way home it was particularly badly behaved – and it was during one of these episodes that the car bucked, and I noticed the rpm picked up momentarily and ramped down again. This behaviour was exactly the same as starting a hot engine, with the idle air stepper opening to its full position and then rapidly closing down. This was my eureka moment and I realised that the car was effectively dying for a split second and then “restarting”. The ecu sees rpms below a certain threshold as “cranking” and then it was picking up again into the normal “run” mode. I added an extra gauge to the dashboard layout on my phone for “Lost sync counter” and saw this incrementing everytime the car sputtered. This confirmed my suspicions, so now I had to find out what was causing it.

Reviewing the logs again I found a field that I had not previously checked “Lost sync reason” and this was giving a reason “15” for every event in the log. This denotes a loss of communication with the EDIS module.

I checked all power feeds and earths to the MS and the EDIS and everything was fine and secure, I then decided to check my HT leads as if one had gone bad then the electrical noise could be enough to cause the resets.

All HT leads were removed, visually checked and measured for resistance. Most were between 9-12kOhm, apparently 5k is the minimum needed. Cylinder 3 was not good and had corroded green at the coilpack end – I must not have seated the boot down correctly. Its resistance was measured at 15MOhm! The terminal was cleaned up, but the end of the cable was in too bad a state, so I shortened it and re-terminated it with a new connector.

I am happy to report that since then all of my reset issues have gone, and what it shows really is how powerful MS can be with its ability to datalog and really review what is going on with your engine.

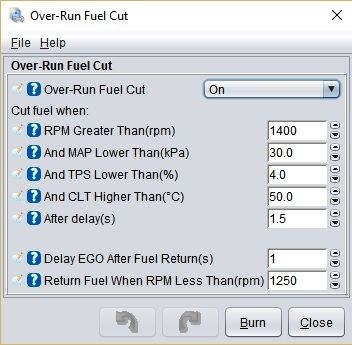

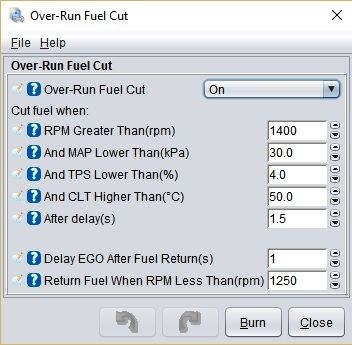

One last change I have made was to fit a throttle position sensor on a couple of weeks ago. This has allowed me to enable overrun fuel cut for the first time, so that under certain conditions the ECU will shutdown the injectors just as a modern vehicle does.

The first tank I had a really bad week of traffic and still got 25mpg - I have since been down to Cardiff for the weekend, as pictured here with my mate Tim:

Filling up down there, and again later in the week back at home i got 27.5mpg on both tanks. Promising!

Looking forward I have the 5 speed still sat in the garage looking at me, and perhaps (if I can collect the bits I need) I might try to get this in during the early autumn this year.