pardonthewait wrote,...

Having trouble picturing this - because I took the carbs apart to replace the float needles/seats, a lot of what I've seen of the inside of the carbs is upside down and dismantled so I'll go through it now to get it in my head. So if I take the dashpot off, I can remove my piston and the needle will be poking out from there - so I want to be adjusting the jet until it makes contact with a straight edge across the bit I've now exposed?

There is no need to remove the dashpot and piston in order to set the jet height, although you can if you wish.

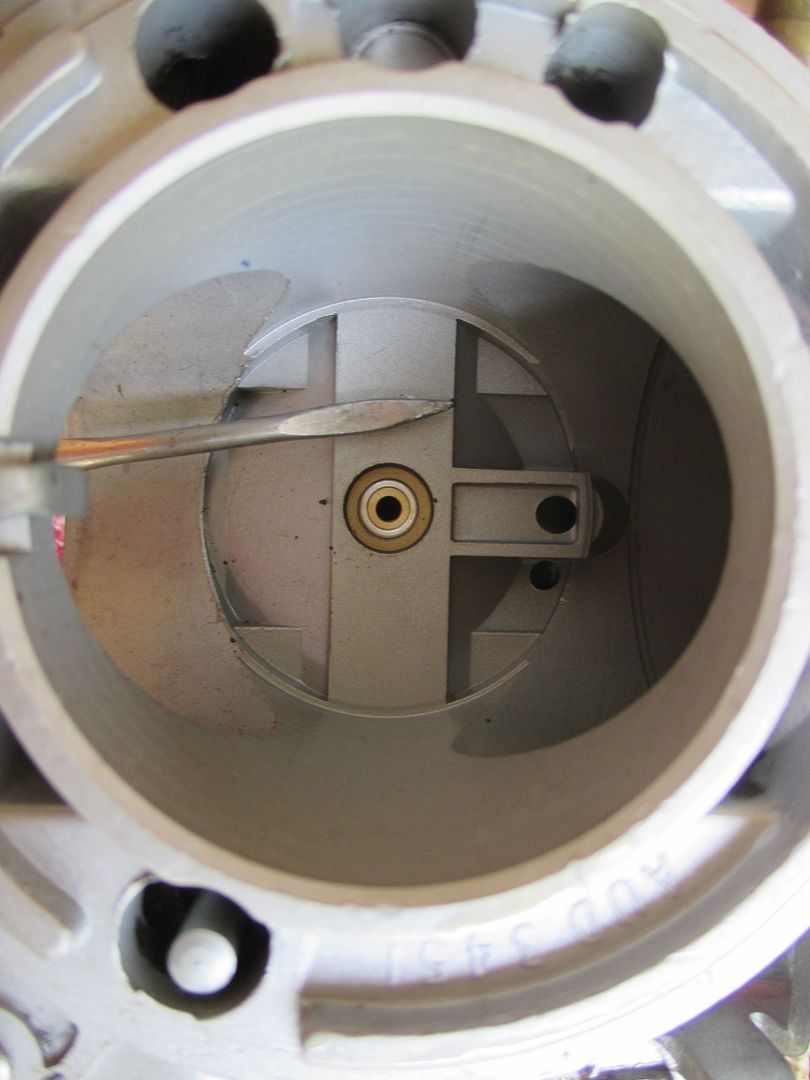

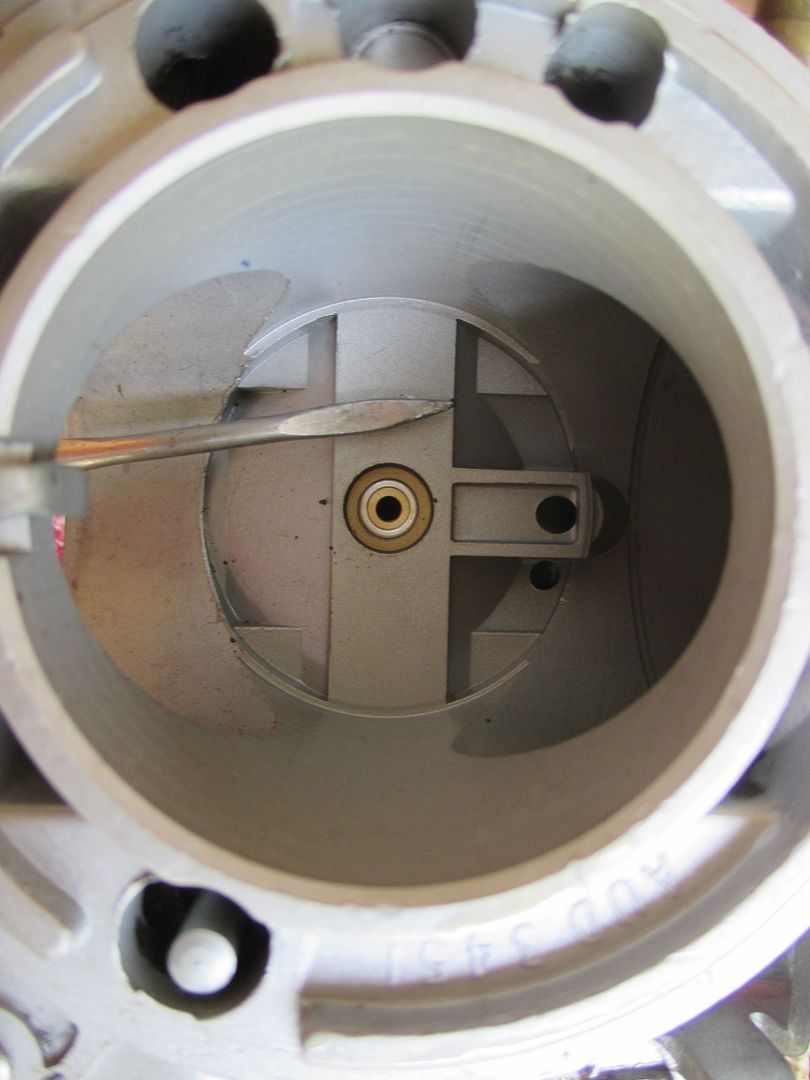

You will need to remove the adapter that attaches to the elbow side of each carb though. This will allow the straight edge to be placed directly on the top of the bridge. The bridge is the raised rectangular section that the jet passes through when you wind it right up.

With the straight edge in place, wind the mixture screw out. This raises the jet, which will make contact with the straight edge. Once contact is just made, (you don't want the jet to lift the straight edge at all), note the position of the mixture screw and then wind in by 2.5 turns. This will then give you the initial setting which will be extremely close to the mark. From here, any adjustments can be made later, but will only be fractions of a turn in either direction. In any case, both jets need to be set exactly the same. If they have to be different in order for the engine to run properly, then there is something wrong, and that will require investigation.

I have taken some photos so as to provide further assistance. They are of a spare set of HIF6 carburettors that I have.

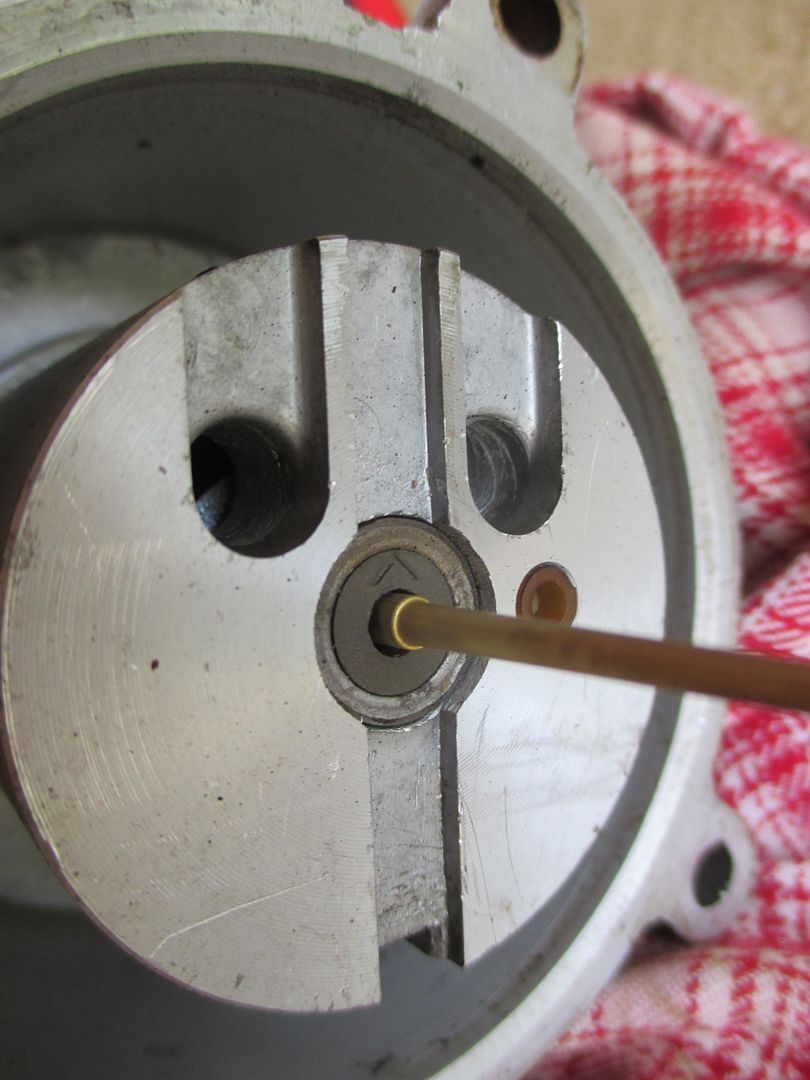

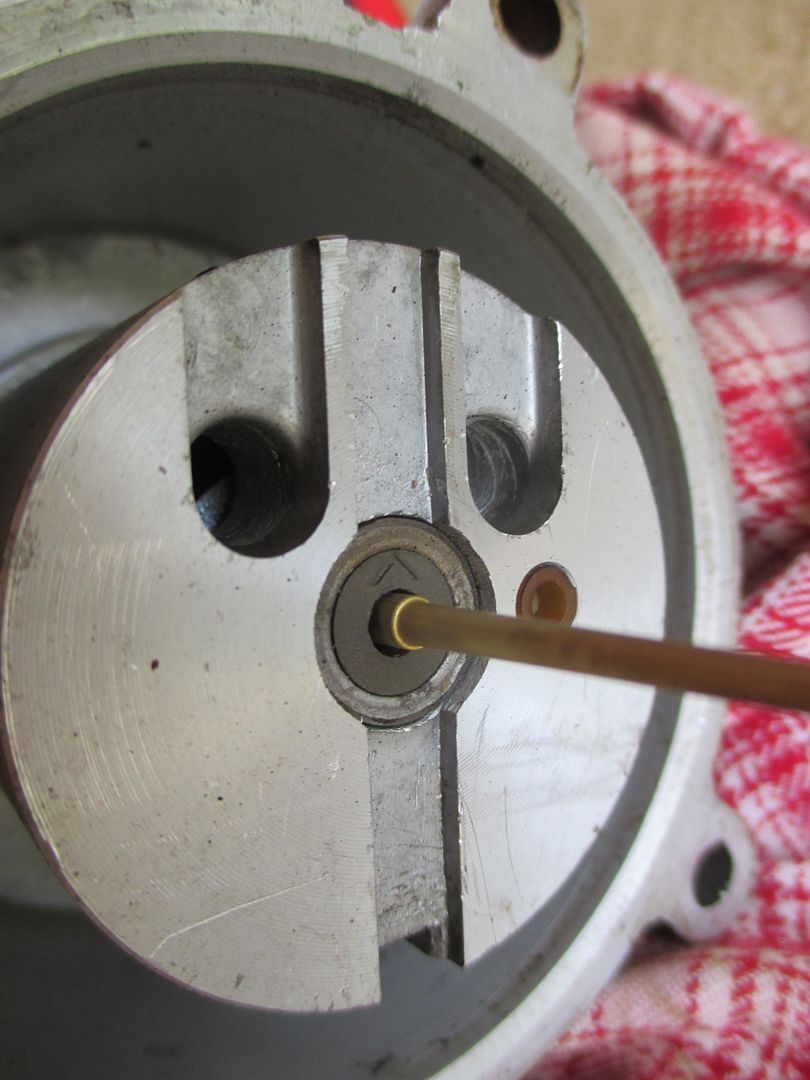

The collar is located flush with the piston base, the arrow points as shown, the needle is thus automatically biased in the right direction.

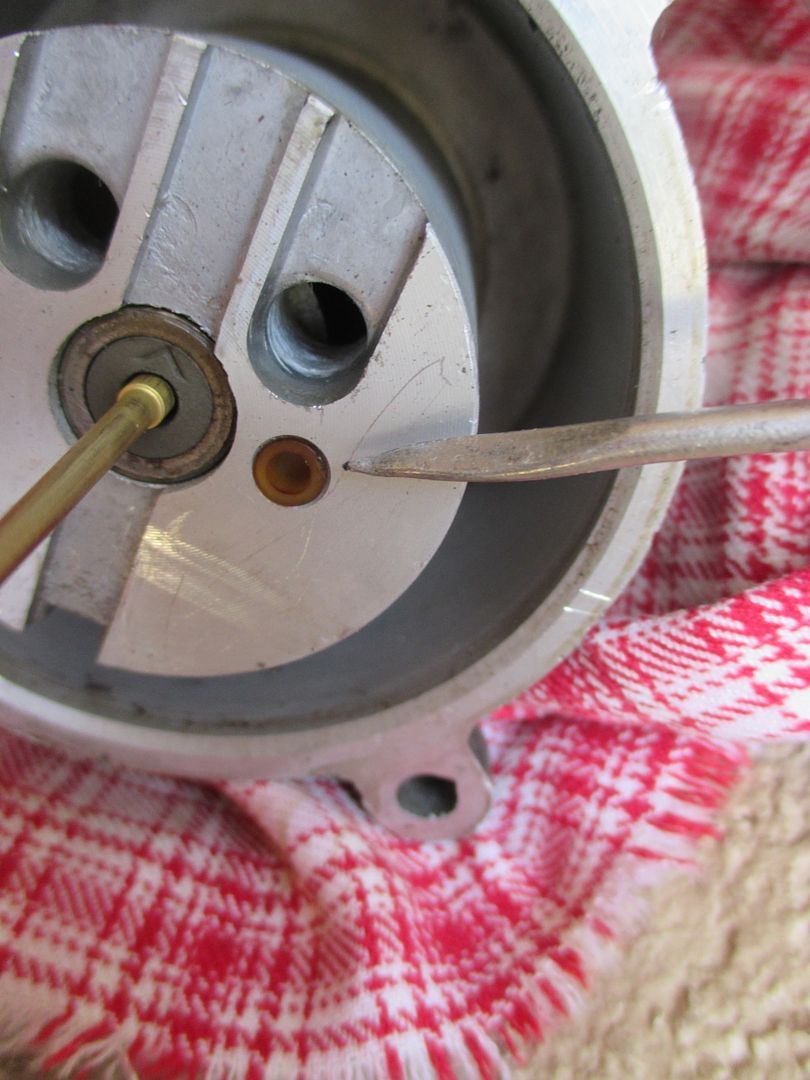

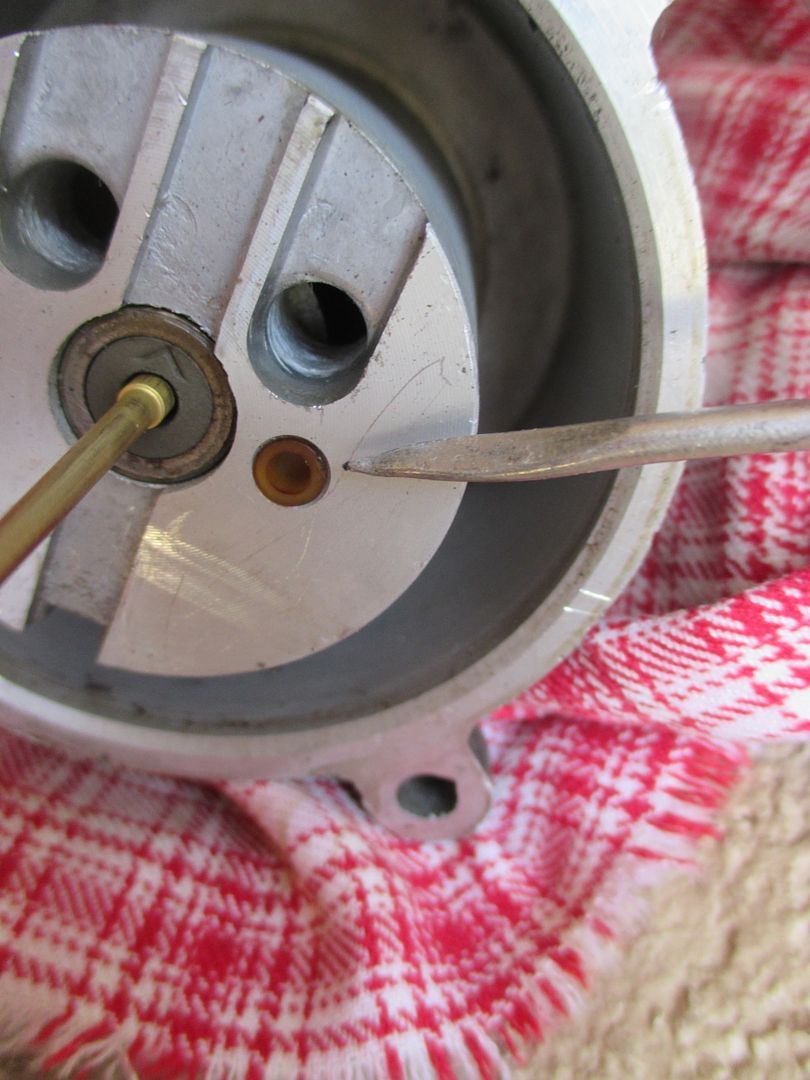

The nylon plug that is being indicated needs to be just proud of the piston surface. This prevents the piston from sitting directly across the surface of the bridge. Ensure that this is the case.

The scribe rests upon the surface of the bridge.

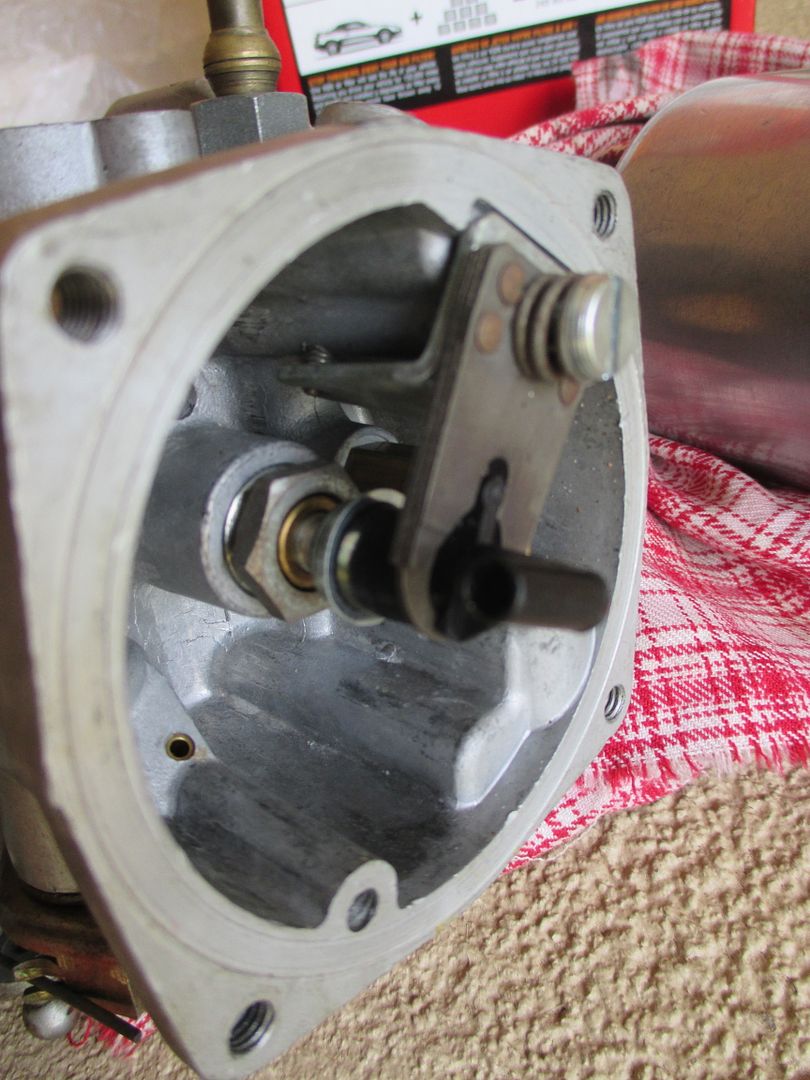

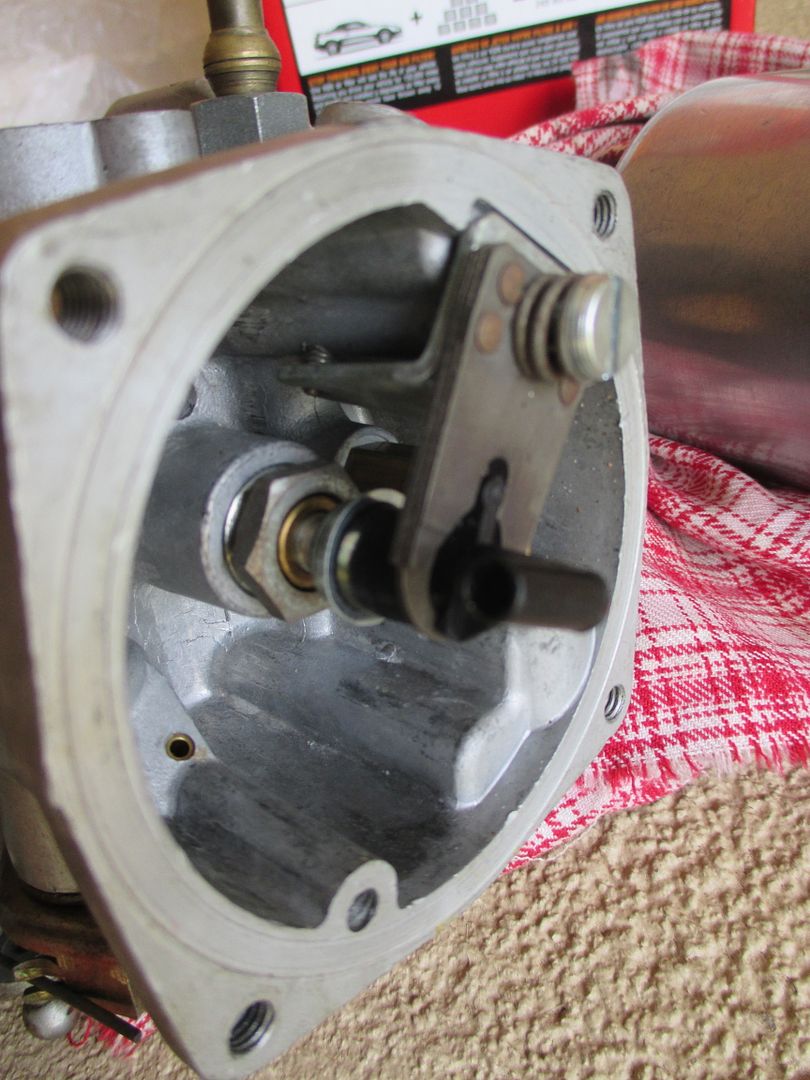

The jet passes through the jet bearing. The bimetalic strip locates the jet. The mixture adjustment screw can also be seen. Although not clear in the photo, the jet has an 'L' piece on the end.

Ron.